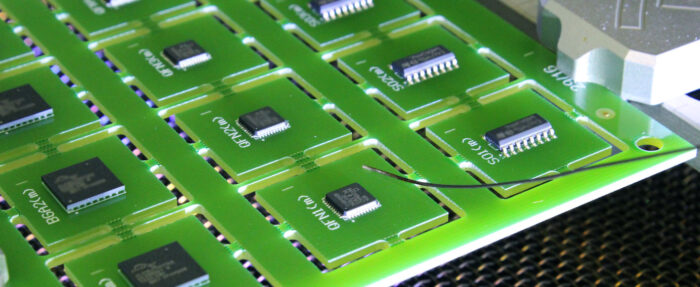

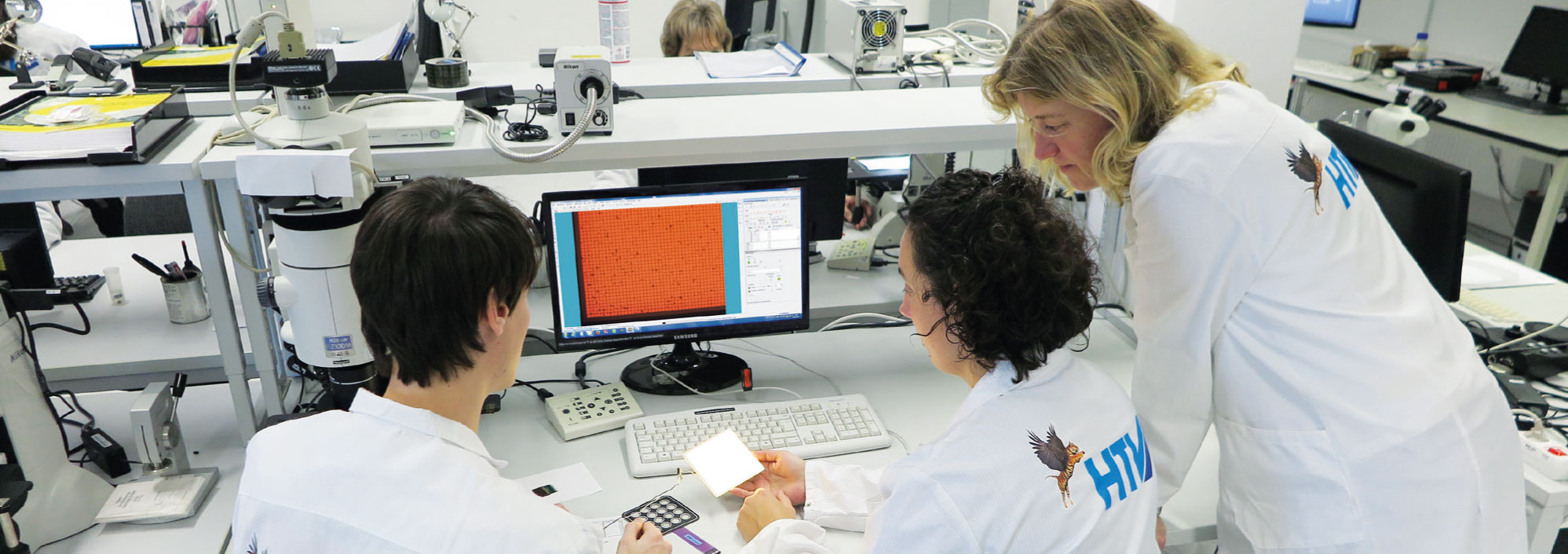

The HTV corporate group represents extensive technological compentence, the highest possible quality standards and over three decades of experience in regards to providing services for electronic components.

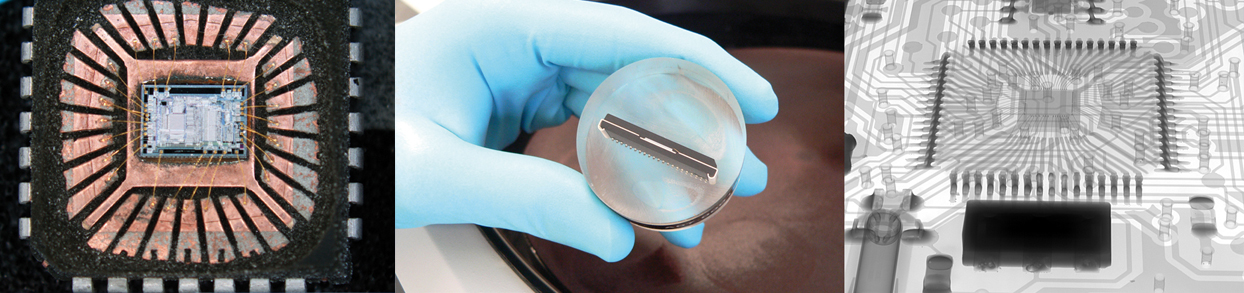

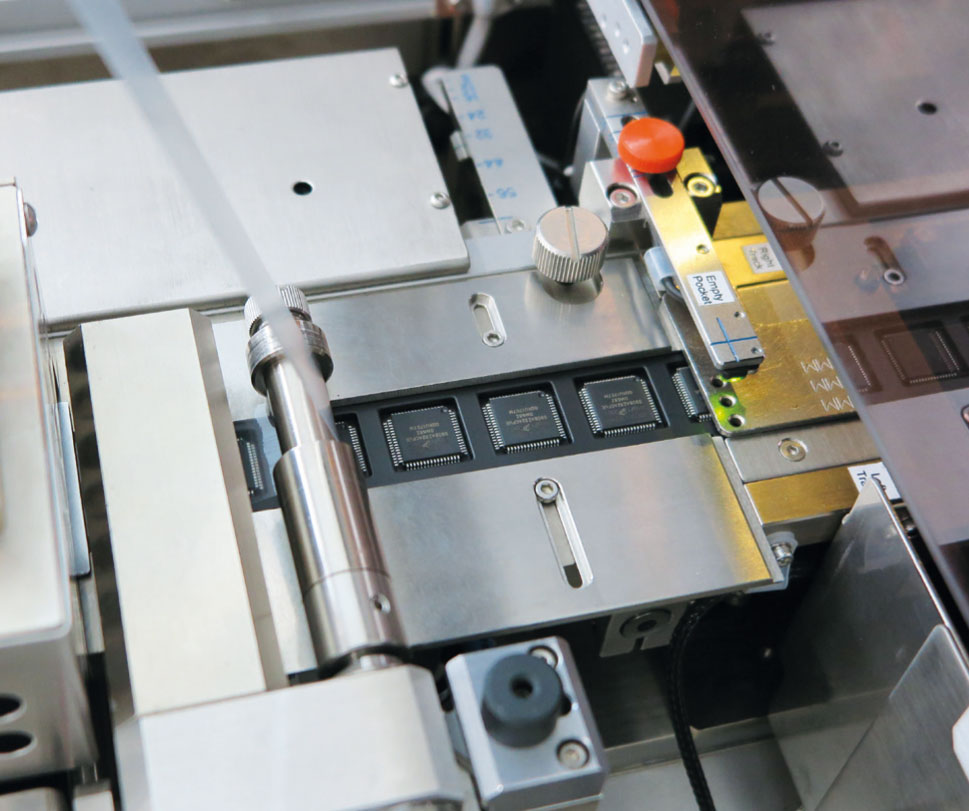

State of the art machinery, continously growing and being adapted to the ever rising challenges of material testing and analyses, as well as teams consisting of over 150 engineers, scientists, technicians and specialists allows us to gain detailed insight into every aspect of electronic components, even down to the deepest level of construction.