Analyzing the quality of raw (unprinted) circuit boards and assemblies in accordance with IPC-A-600 and IPC-A-610

Applied Standards

- IPC-A-600

- IPC-A-610

- IPC-TM-650

- J-STD-001

- J-STD-003

- DIN EN 60068-2-69

- DIN EN ISO 3497

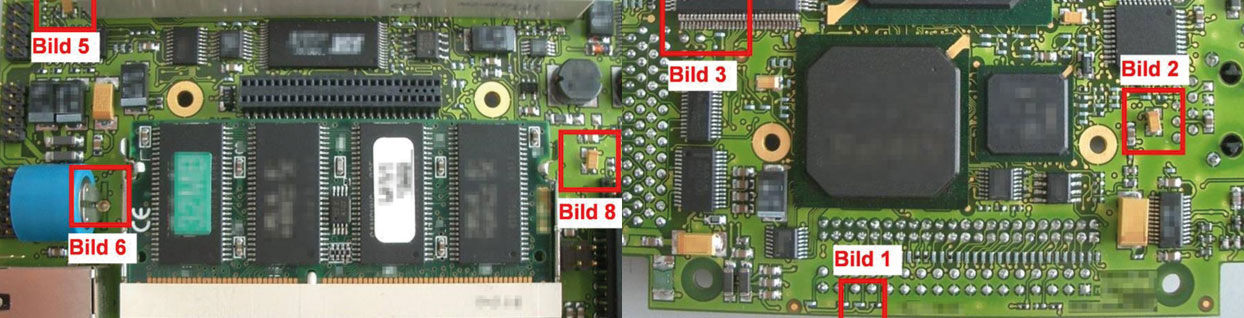

HTV analyzes assemblies and raw (unprinted) circuit boards comprehensively and highly precise, using various processes and methods of quality control in accordance with IPC-A-600 and IPC-A-610.

Analyses in accordance with IPC-A-600

The commonly accepted guideline IPC-A-600 contains specifications in regards to evaluating the composition of raw (unprinted) circuit boards to ensure flawless and reliable assemblies, devices and systems.

At the HTV Institute for Material Analysis their IPC certified specialists analyze raw (unprinted) circuit boards in regards to the following characteristics:

Visible exterior characteristics:

- Base material surfaceBasismaterialoberfläche

- Holes and contacts

- Conductive pattern

- Soldermask

- Solder coatings

- Labeling

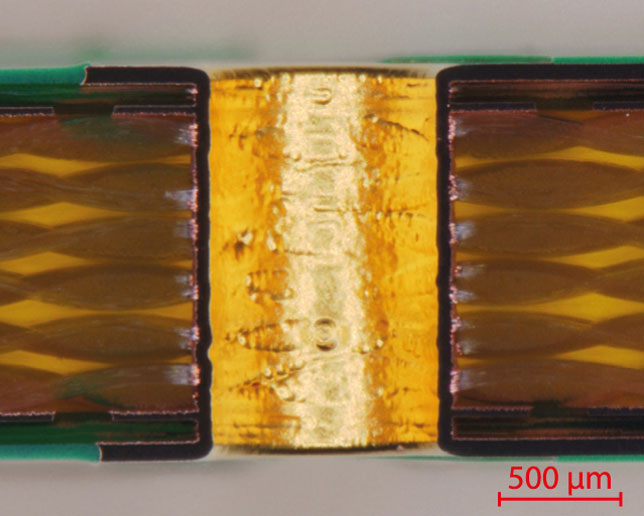

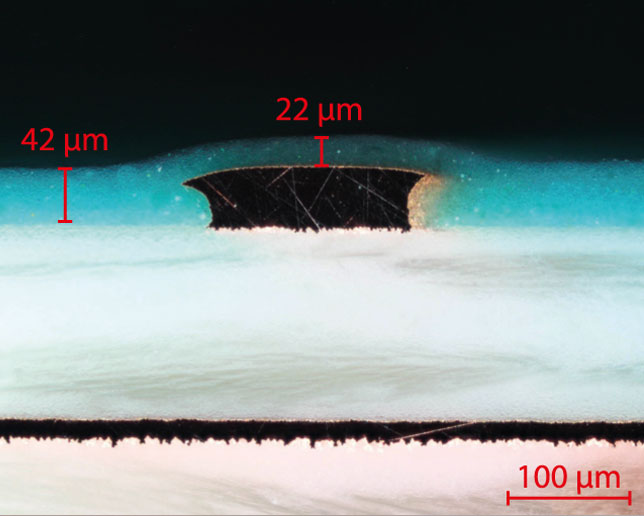

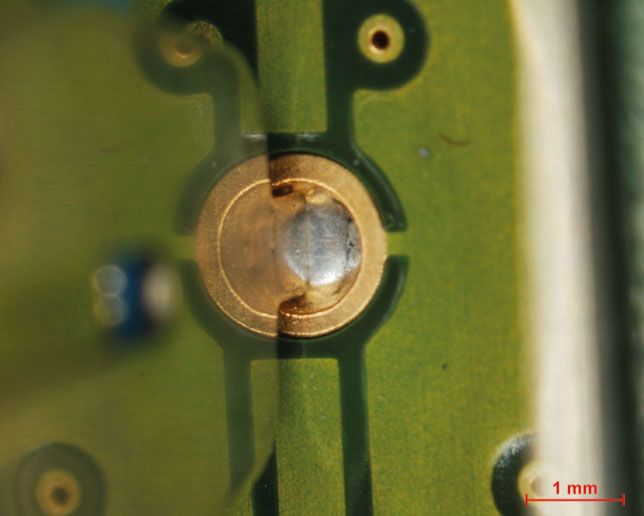

Interior characteristics (microsection):

- Registration of the conductive and hole pattern

- Evaluating the conductive pattern and the base material regarding etching characteristics, conductor thickness, foil thickness, layer spacing, insulation spacing, blind and/or buried vias, grate and/or nail head formation, metallization thickness, residual ring, solder resist thickness, burrs, roughness, buds, funnels

- Characterizing flaws in the laminate (outside of the thermal zone) such as delamination or bubble formation, separation of inner layers, fractures in the metallization and in foils, etchback, raised connection surfaces, incomplete metallization (holes)

- Acceptance criteria for flexible and rigid-flexible circuit boards as well as metal core circuit boards

- Measuring ionic contamination

- Solderability test

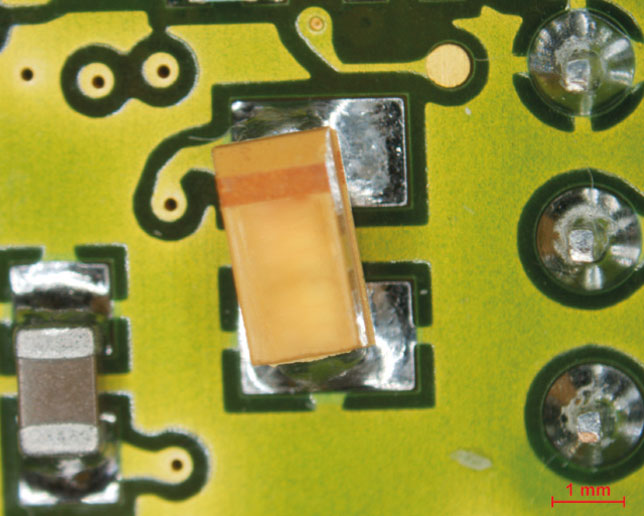

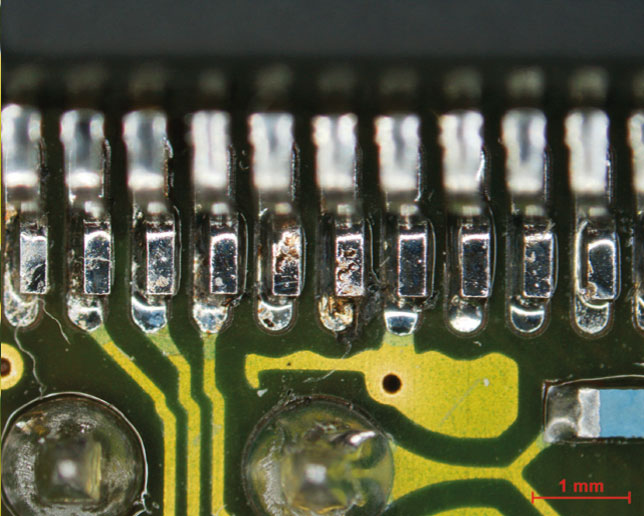

Analyses in accordance with IPC-A-610

The IPC-A-610 guideline is the foundation for visual non-invasive assembly testing. At the HTV Institute for Material Analysis their IPC certified specialists evaluate the quality of assemblies using the following criteria:

- Assembly and fastening parts:

Installation of fasteners, connectors, handles, pull-out devices - Solder joint:

Acceptance requirements, anomalies - Terminals:

Edge clips, rivet joints, wire/terminal placement, insulation, solder terminals – solder - Through-hole mounting technology:

Component assembling, component retention, plated and non-plated through-holes - Printed circuit boards and assemblies:

Laminate requirements, labeling, coating - Individual wiring:

Solder-free winding technology, wire bridges, cable preparation to relieve strain or stress relief

A detailed IPC-A-600/610 analysis report including a substantial image documentation gives a comprehensive synopsis of the printed curcuit board’s or assembly’s current state.