PFAS substitute qualification at the HTV ALTER TECHNOLOGY GmbH’s Institute for Material Analysis

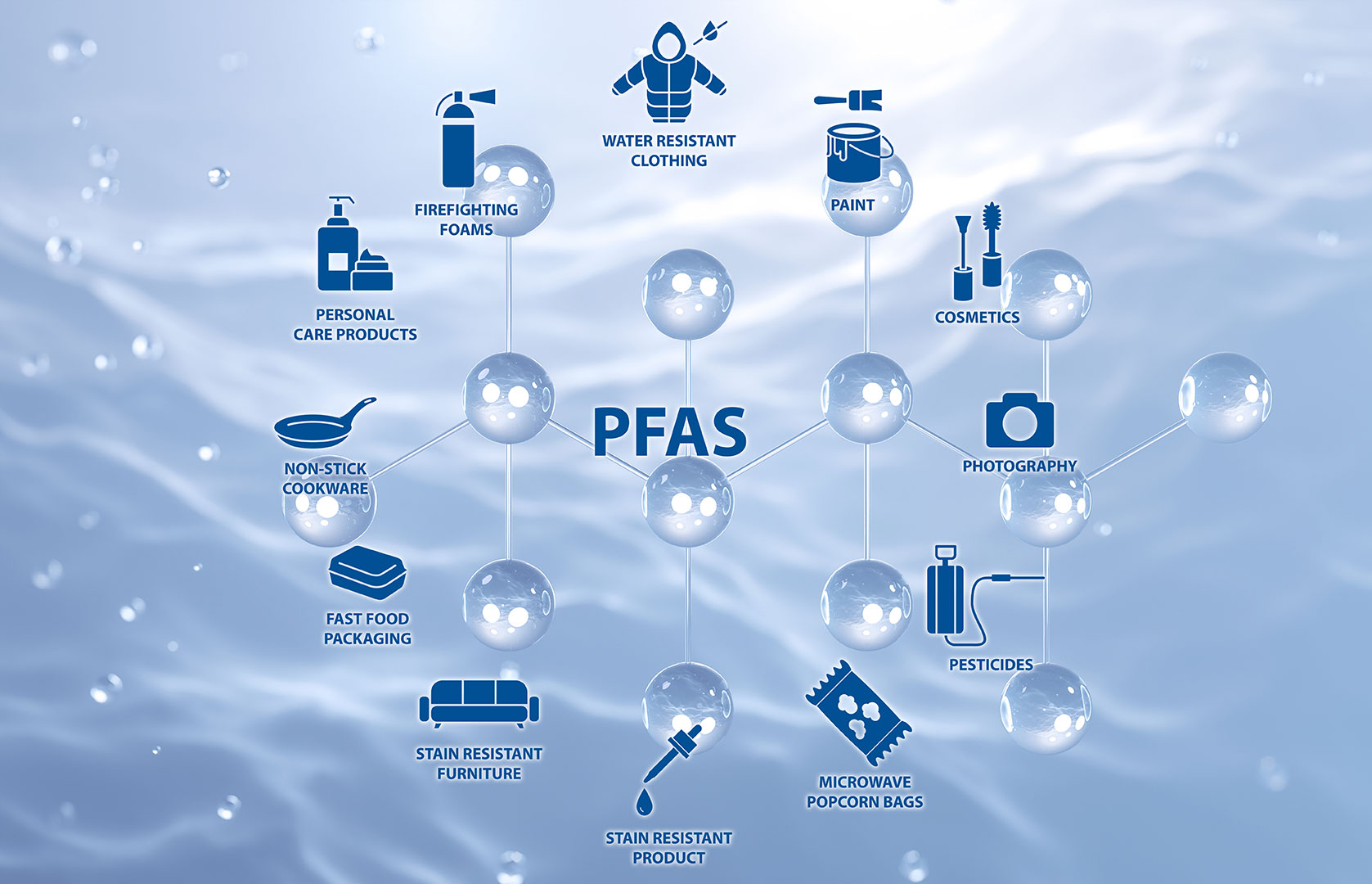

Since the 1950s, per- and polyfluoroalkyl substances (PFAS compounds) have seen usage in various applications, from coatings to chemical fire inhibitors to sealants as well as in medical technologies, owing to their remarkable stability under diverse chemical and thermic environmental influences.

This persistence has also caused these PFAS compounds to permeate the environment more and more; these days most people tested for such substances show traces of PFAS compounds in their blood.

Since these chemicals disintegrate only extremely slowly they have been dubbed ‘eternity chemicals’. PFAS compounds are suspected to be both carcinogenic and cause other serious health problems, which is why the European Chemicals Agency (ECHA), under the leadership of five EU member states, has put forward a motion to prohibit the use and circulation of PFAS compounds. Several companies using PFAS compounds have already begun looking for alternatives to PFAS products.

The HTV ALTER TECHNOLOGY GmbH’s Institute for Material Analysis is your support in the search for alternatives to PFAS products, by testing and qualifying substitutes for your applications.

Our climatic lab allows us to test the resilience of your substitutes under controlled conditions and document the results of the climate stress tests.

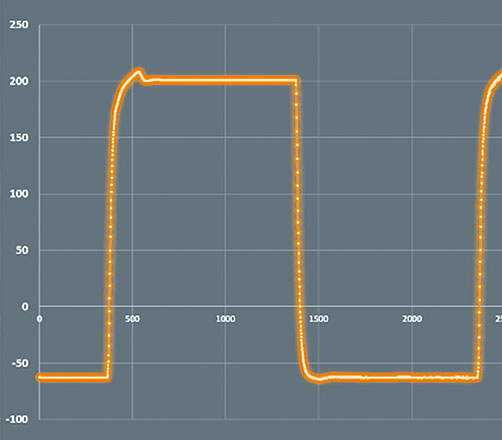

As per your specifications we can stress test your materials in various different ways, such as temperature storage ranging from -60°C(-76°F) to +250°C (482°F). Our climatic chambers are capable of both constant as well as cyclic temperature stress tests.

Our shock furnaces can recreate rapid temperature changes ranging from -60°C (-76°F) to +200°C (392°F) in a span of a few minutes.

We are also capable of inducing aging processes, using a photochemical stress under UV light. The material is subjected to UV light (wavelength of 254 nm / UV-C) for a predetermined time, followed by an analysis of changes inside the material.

Our methods for testing climatic resilience:

- static climate treatment (consistent parameters)

- dynamic climate treatment (various different parameters)

- temperature storage (ranging from -60°C(-76°F) to +250°C(482°F))

- dynamic high temperature storage/temperature change stress test

- temperature shock (ranging from -60°C(-76°F) to 200°C(392°F))

- tests performed under controlled temperature and moisture levels (constant or cyclic)

- pressure cooker-tests, such as the highly accelerated stress test (HAST)

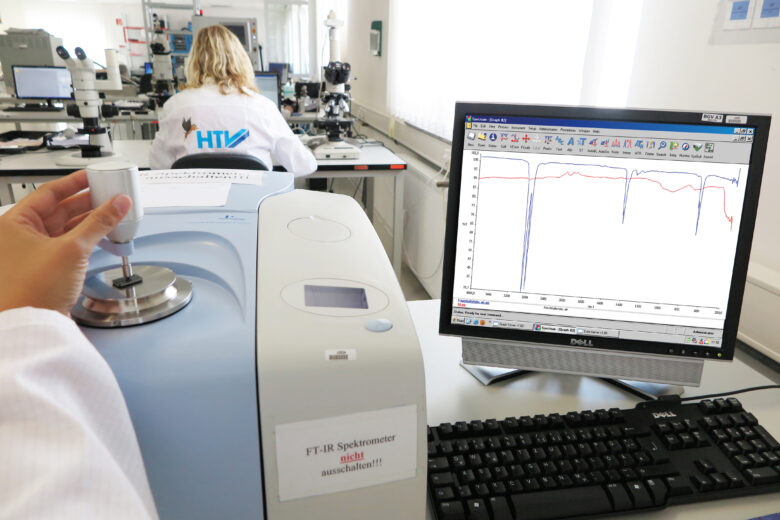

Following the climatic treatment, any changes in the material are analyzed at the HTV ALTER TECHNOLOGY GmbH’s Institute for Material Analysis to document your materials’ resilience. We can ascertain possible materiel degradations in the plastics using Fourier-transform infrared spectroscopy (FTIR). Changing or newly appearing absorption bands indicate molecular changes. Analyzing the nature of these changes in the spectrum allows us to deduce their mechanisms.

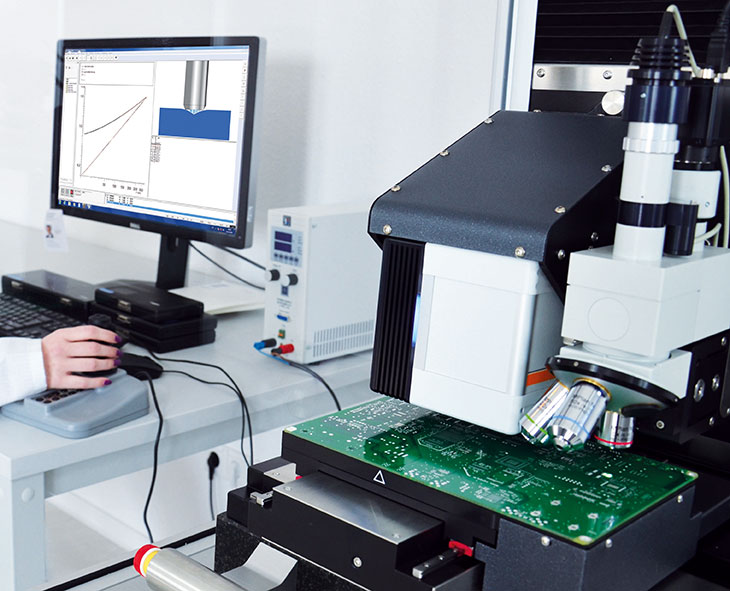

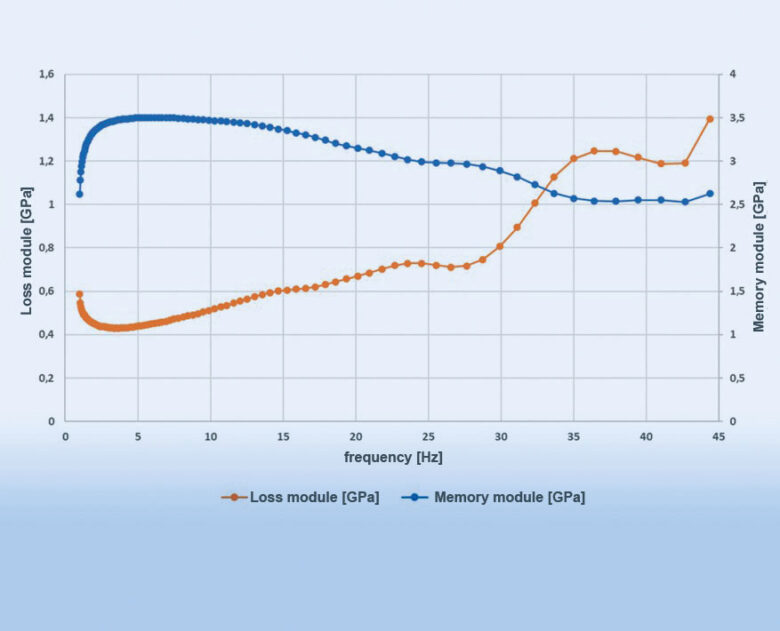

We document changes in the material’s mechanical behavior, which we previously induced via climatic or UV treatment, using instrumented penetrant testing. With these indentations perpendicular to the material we can evaluate layer adhesions or ascertain changes in the material’s hardness, both depending on the layer thickness. Using dynamic measurings during which the sample is cyclically put under strain while being indented, we can gain information regarding the storage modulus, the loss modulus and the phase shift. By taking comparative measurings prior to and after the induced aging we can document the changes inside the material. We can even record and visualize the creep or cold flow behavior with this method.

PFAS substitutes have to fulfil many requirements, which makes having proof of their qualification just as if not even more important. The HTV ALTER TECHNOLOGY GmbH’s Institute for Material Analysis with all its capabilities is your undeniable partner regarding material testing. We are offering you our full support in a comprehensive qualification of your PFAS substitutes.

Get in touch!