HTV light laboratory:

Light-based measurement technology of optoelectronical components

Possible methods:

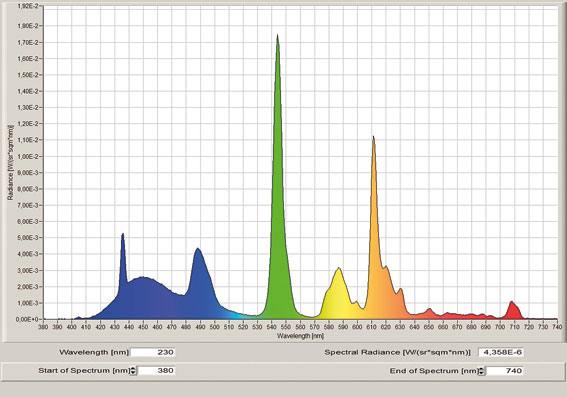

- Radiometric spectral measuring, for example:

- Beam strength [W/sr], radiation intensity [W/qm]

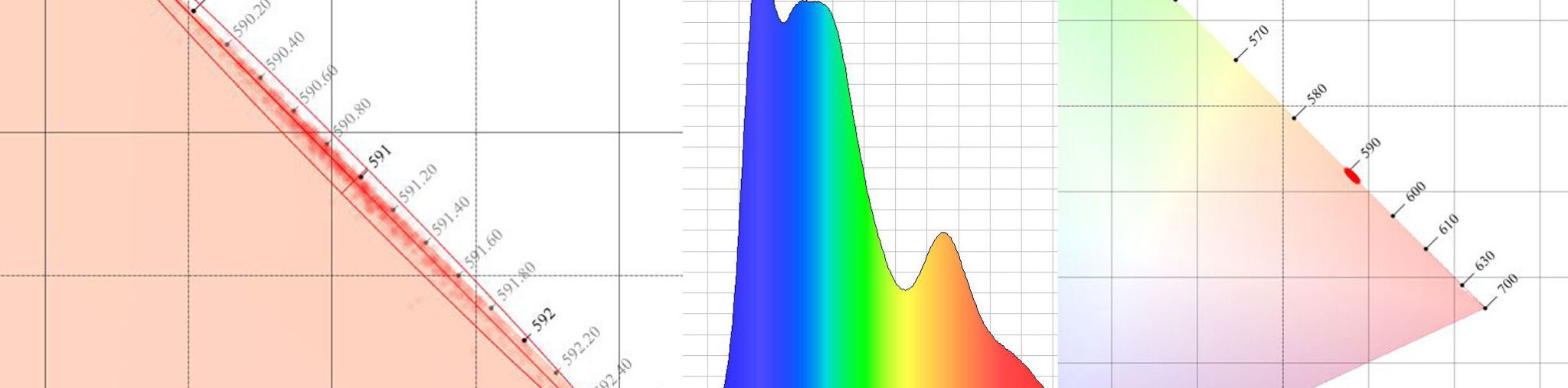

- Spectrum [W/sr/nm], peak wavelength, centroid wavelength, full width at half maximum

- Photometric spectral measuring, for example:

- Spectrum, dominant wavelength

- Luminous intensity [cd, mcd] and illuminance [lx]

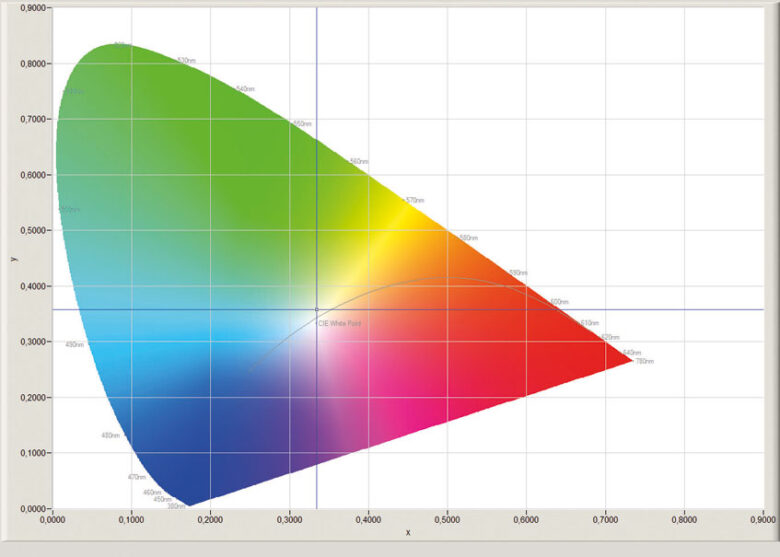

- Color coordinates (x,y) and color spaces: CIE RGB, CIE XYZ, CIE LAB (L*a*b*)

- Surveying/Measuring of displays (z. B. LCD, OLED)

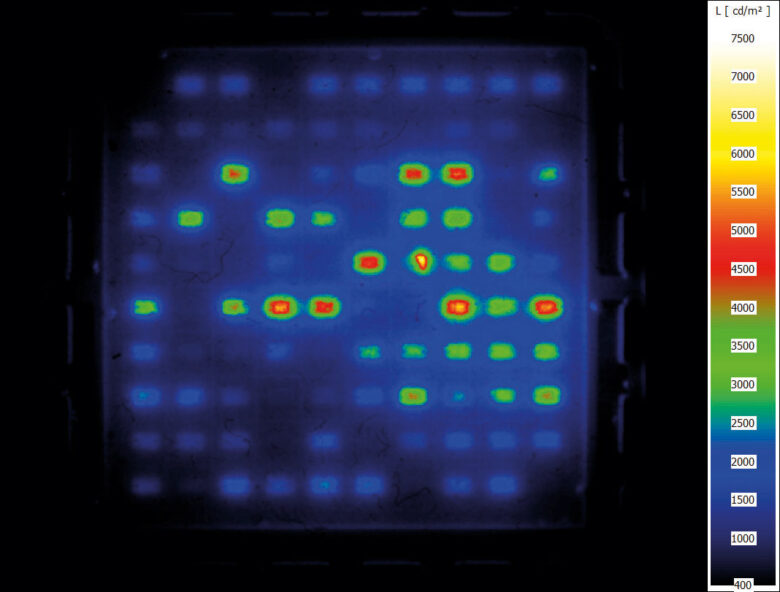

- Spatially resolved luminance measuring

- Measuring the homogeneity of LED arrays and clusters

- Full characteristics determination of displays (brightness, color points, contrast, homogeneity)

- Measuring of any variety of optical parameters as per customer request

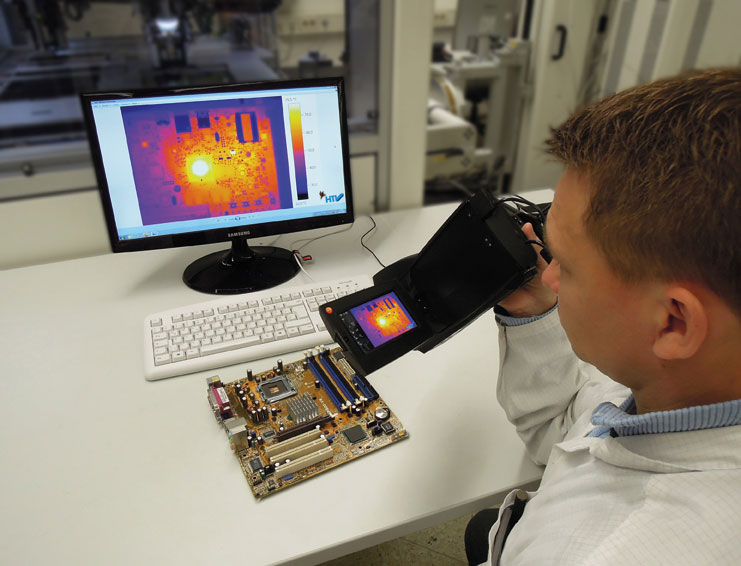

- Industrial thermography via thermal imaging camera

A product’s success is not just determined by the general quality and functionality of assemblies, for example, displays or illuminants, its photometric characteristics are an important factor as well, especially from a marketing angle. This places a huge importance on the long-term stability of luminous intensity, of the light’s color spectrum as well as color rendering and contrast, among other things

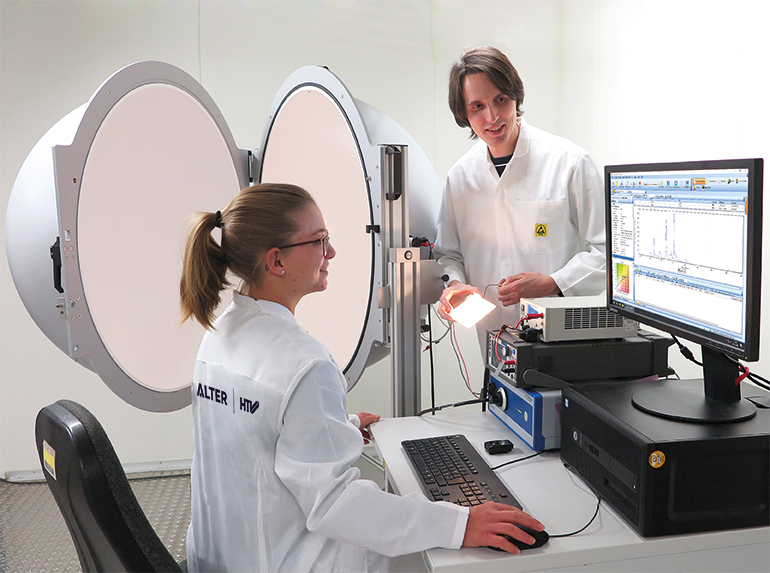

Thanks to fully automated and configurable measuring workstations HTV is able to evaluate optical parameters according to a datasheet or a customer’s specific requirements for orders of any size, small and large quantities. Radiometrical or photometricalspectral analysis enables the characterization of LED, OLEDs, lamps and other light sources according to their radiant power and intensity, beam strength, luminous intensity and illuminance.

HTV does not just analyse singular LEDs or light bulbs, but also displays or illuminated complex arrays as well (for example, switches, buttons, captions/labeling, backlightings). A spatially resolved measuring of luminance allows for characterization of the brightness, contrast and homogenity of dispays, as well as analyzing the contrast behavior of a display from many different angles, which is one of the important factors in assessing a display’s overall quality.

Many applications necessitate a selection according to certain photometric values (for example, dominant wavelength, color location, luminous intensity). However, more often than not optical parameters of, among other things, LEDs change during their first hours of operation. For example, the differing strength in the drift of an LED’s dominant wavelength might change which optical impression an observer will receive, or worse, it might influence the calibration of a medical technological device. Using a burn-in, a process of artificial aging, HTV is able to prevent early failures, stabilize photometric properties and select components according to their parameters. Unstable LEDs or displays (for example strong deviations in color location) are removed.

Industrial thermography via thermal imaging camera makes it possible to identify heat sources and hot spots in assemblies as well as inside devices and systems. A simultaneous recording of infrared and normal images serves to allocate and evaluate the temperature spread.