ALTER | HTV – More than 30 years of testing expertise

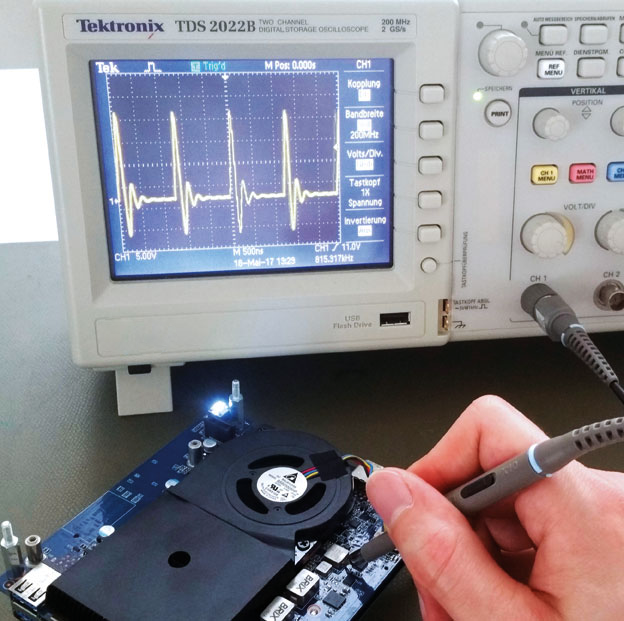

Electrical Testing

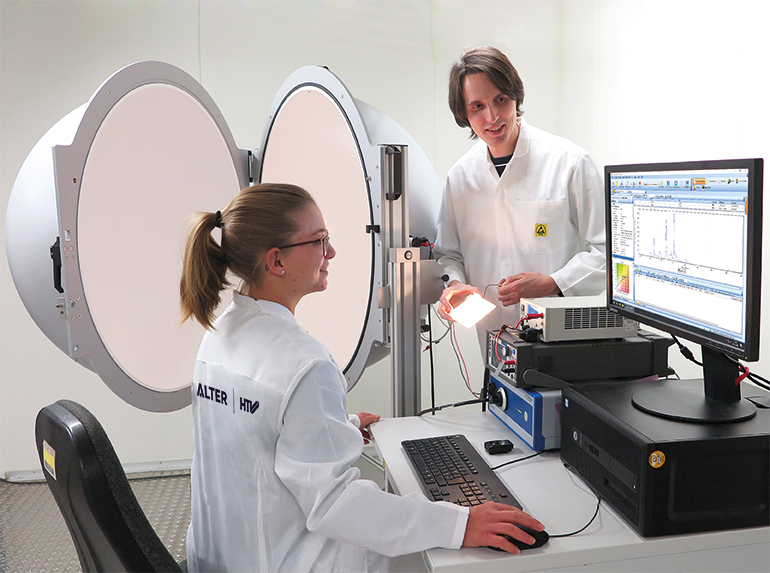

Testing Optical Parameters

Environmental Testing

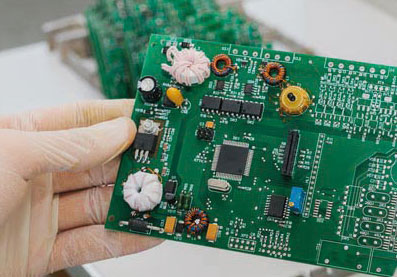

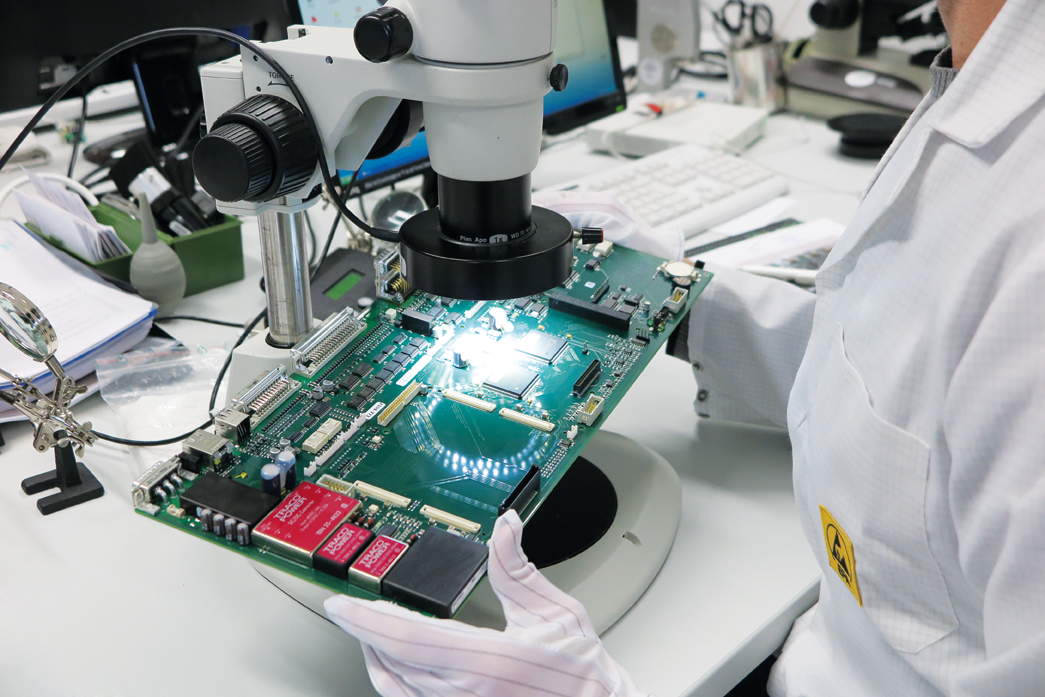

Testing Assemblies

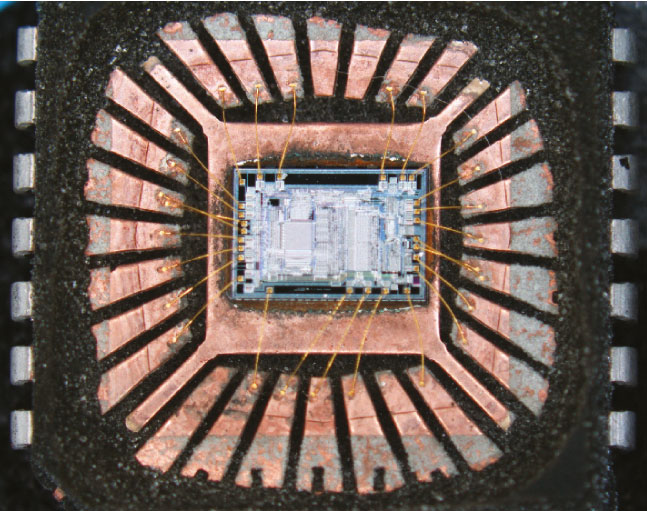

ASIC Design and Testing

packaging >

MTBF Calculation

Failure Analysis

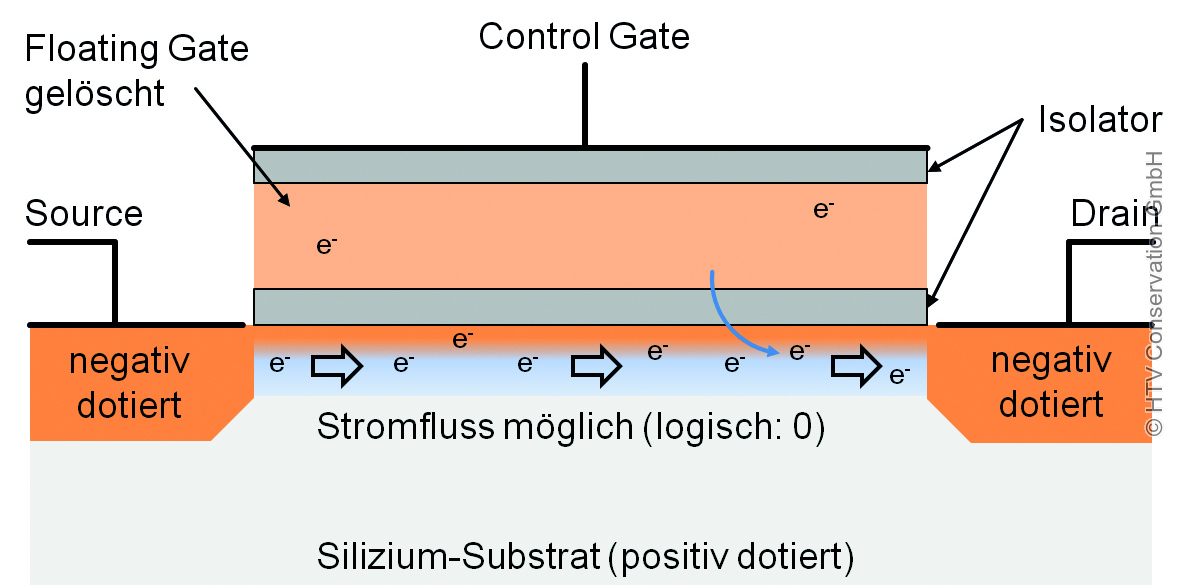

Memory Qualification

Inspection / Function Testing

Mechanical Testing

Developing Testing Software

Material Testing

ALTER | HTV offers comprehensive solutions for testing electronic and mechanical components, even in serial quantities

- Trusted across industries: Companies from such varied sectors as automotive, telecommunications, aerospace, medical technology, and security technology rely on the testing expertise of ALTER | HTV.

- State-of-the-art machinery: Fully automated large-scale as well as custom-developed testing systems enable precise measurements on complex circuits with a capacity of several hundred thousand parts per day.

- Comprehensive testing: Nearly every component can be tested under various environmental temperatures.

- Custom test programs: ALTER | HTV’s development team creates test programs specifically tailored to customer requirements..

- Various component testing: From simple resistors and capacitors to discrete semiconductors like diodes, transistors, MOSFETs, IGBTs, LDOs, DC-DC converters, up to complex circuits like ASICs, tested according to datasheets or customer specifications. Anything is possible.

The newest generation of testing systems

As a consistently forward-thinking company, ALTER | HTV is always committed to keeping its technology up-to-date in a sustainable manner. Two new, state-of-the-art test systems have been enhanced to ALTER | HTV’s extensive machine park.

Key points:

- The Advantest V93K EXA Scale is a state-of-the-art testing system, equipped with the latest operating software, SmarTest 8, offering a wide range of testing capabilities for analog and digital signals..

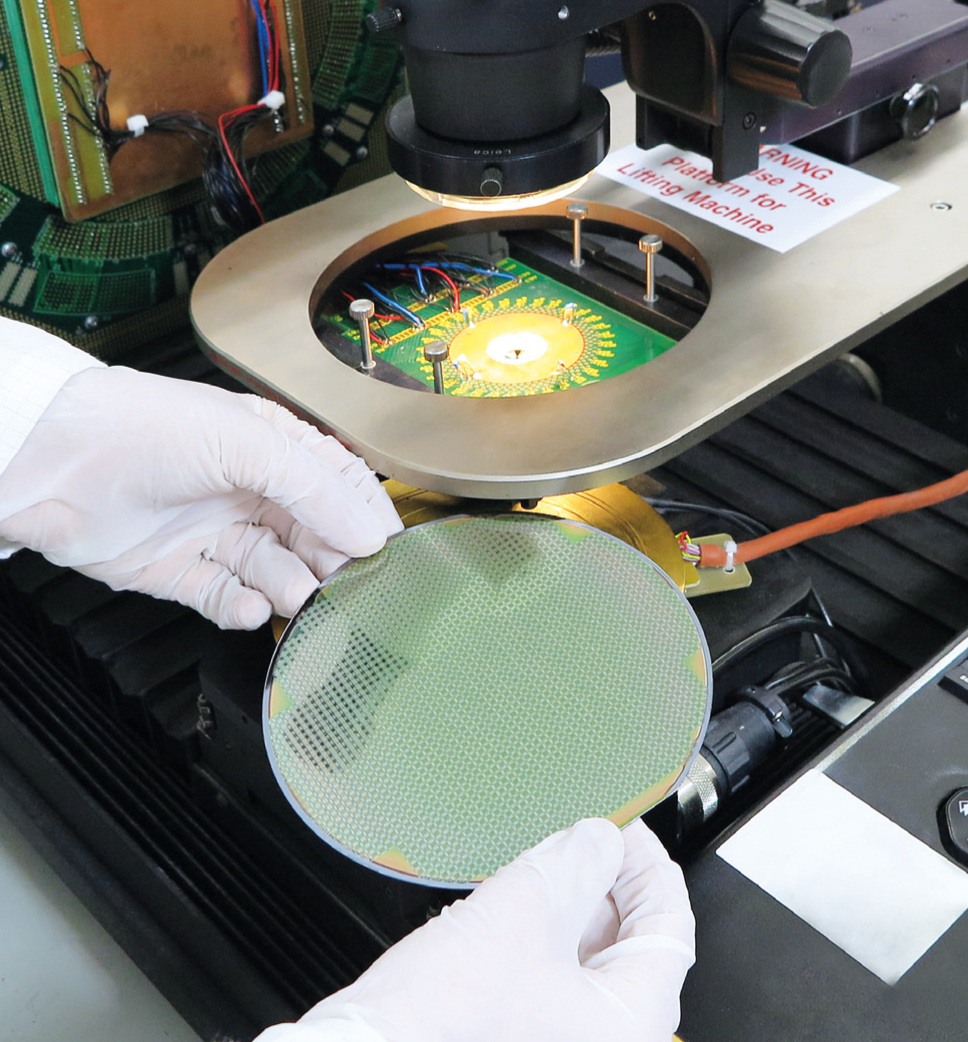

- The ACCRETECH UF2000 enables precise wafer testing with an accuracy of ±1.5 micrometers and is designed for standard 6- to 8-inch wafers.

- Both devices support reliability testing at different temperatures and offer tailored solutions for customer requirements.

The Advantest V93K EXA Scale is a state-of-the-art testing system that will shape the semiconductor testing industry in the coming years with its high flexibility. Equipped with the latest operating software, SmarTest 8, the EXA Scale offers a wide range of testing capabilities for analog and digital signals. This versatility allows ALTER | HTV to respond flexibly to specific customer requirements and offer tailored solutions.”

The fully automated wafer prober ACCRETECH UF2000 is one of the pre-eminent tools for electrical chip testing on a wafer basis. With a precision of ±1.5 micrometers, the UF2000 ensures the highest standards of accuracy. The ability to test at temperatures up to +200°C is an important aspect of reliability testing and characterization of semiconductor chips.