Comprehensive specialized testing and analysis of assemblies

Applied standards

- IPC

- J-STD

- MIL-P

- MIL-STD

- DEF-STD

- IPC-TR

- IPC-TM

- IEC Standards

Possible methods:

- Failure analysis

- Pre-aging

- Prevention of premature failures via accelerated aging tests

- Qualification

- Climatic resistance

- Life-cycle evaluation

- Endurance testing

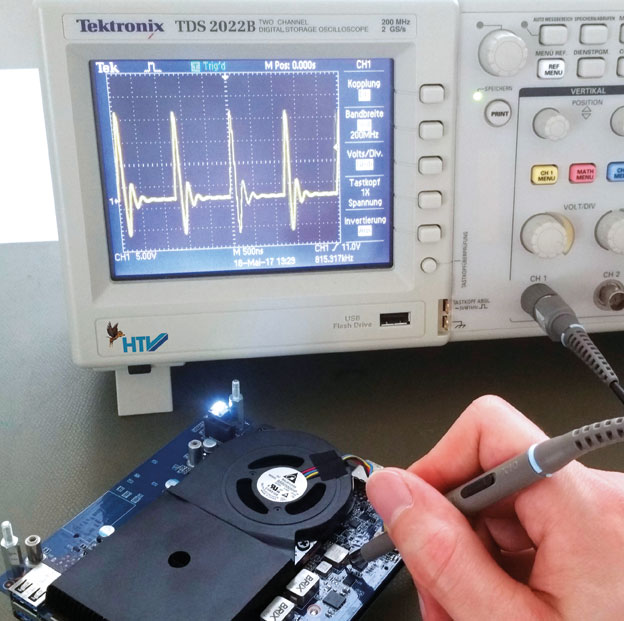

- Parameter testing

- ESD testing (evaluation of component’s vulnerability to electrostatic discharge)

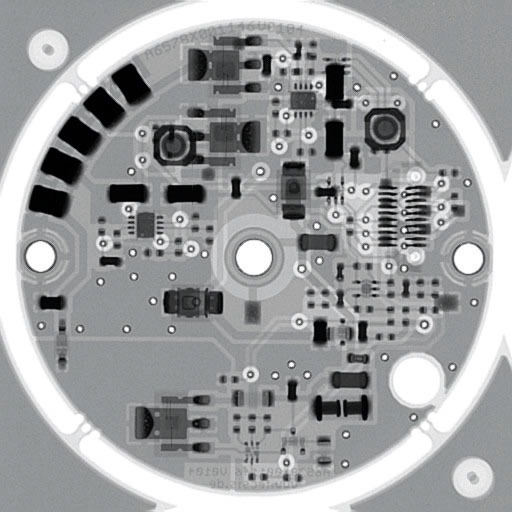

- IPC-A-610/600 analysis

- Standardized evaluation of the quality of assemblies and pre-processed circuit boards

- Ionic contamination measurement

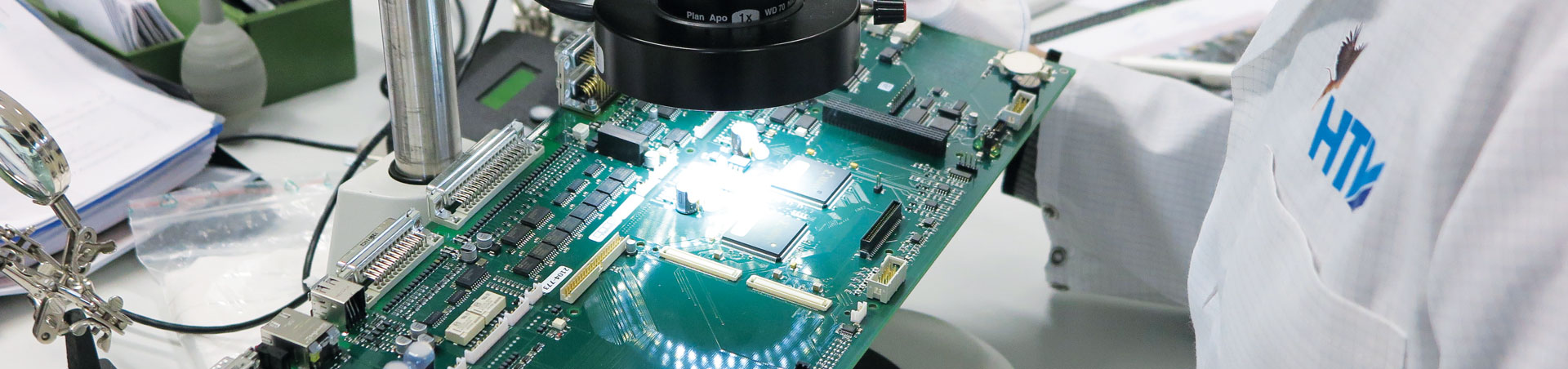

Owing to eventual manufacturing defects it is essential to fully and meticulously evaluate and test assemblies to ensure quality and functionality.

Furthermore, the possible legal requirements regarding product liability can only be met through sufficiently meticulous testing and evaluation. A sensibly planned combination of several testing methods during the development phase can identify and locate possible flaws which may occur due to effects that just cannot be estimated during layout or assembly type design. Refuse to test your assembly and those flaws may escape notice; however, this can quickly lead to manufacturing problems, penalties for breach of contract due to delays in delivery, or legal recourse because your components fail while in use. Enormous financial expenditures and lasting damage of your corporation’s public image will soon follow. It bears repeating: meticulous testing and an individualized testing approach will minimize the risk of assembly failures significantly. At HTV assemblies are being tested and evaluated comprehensively under high-precision conditions using multiple various processes in accordance with customer specifications or current standards (i.e. IPC-A-610). Individual testing devices and compatible software may be developed in-house, if necessary. Thanks to a multitude of specific analytical methods any occurring error may be thoroughly examined and its cause definitively identified and analyzed.