Goods evaluation to uncover component counterfeiting or manipulation (fakes)

Applied standards

- AS6081

- IDEA-STD-1010

- MIL-STD-202

- MIL-STD-883

Areas of application:

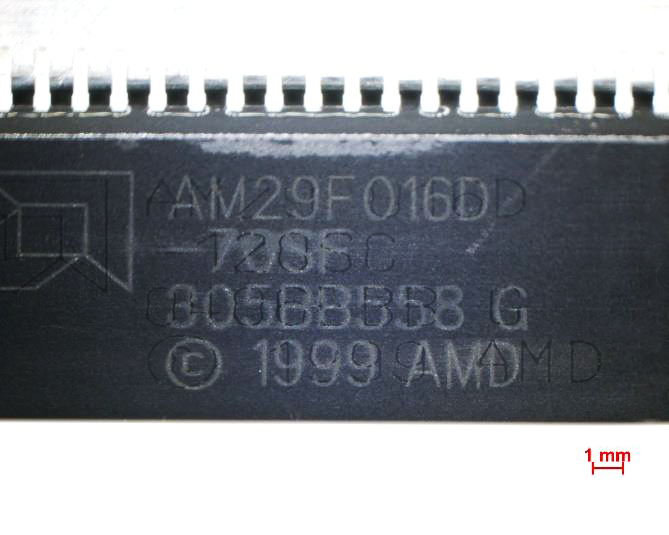

- Analysis of markings in case of suspected remarking

- Wipe and solvent resistance tests, light (optical) microscopy, scanning acoustic microscopy

- Wipe and solvent resistance tests, light (optical) microscopy, scanning acoustic microscopy

- Analysis of housing surfaces in case of suspected re-surfacing or other manipulations

- Wipe and solvent resistance tests, light (optical) microscopy, SAM, REM/EDX

- Wipe and solvent resistance tests, light (optical) microscopy, SAM, REM/EDX

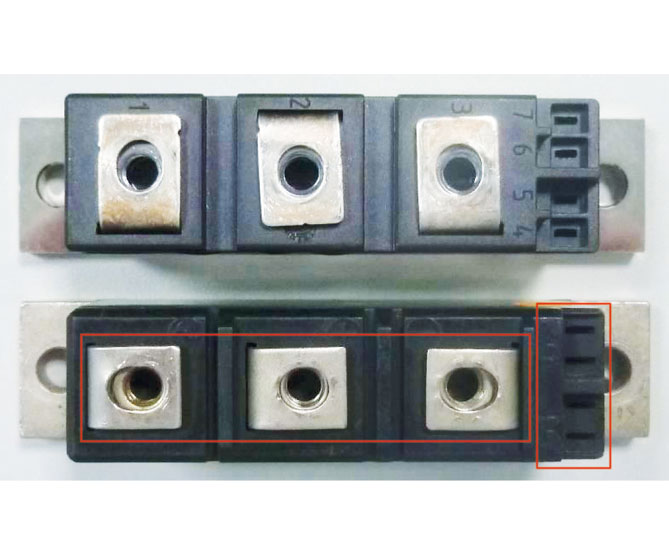

- Analysis in case of suspected refurbishing (used components are being made to look brand new)

- Wipe and solvent resistance tests, light (optical) microscopy, X-ray inspection, XRF

- Wipe and solvent resistance tests, light (optical) microscopy, X-ray inspection, XRF

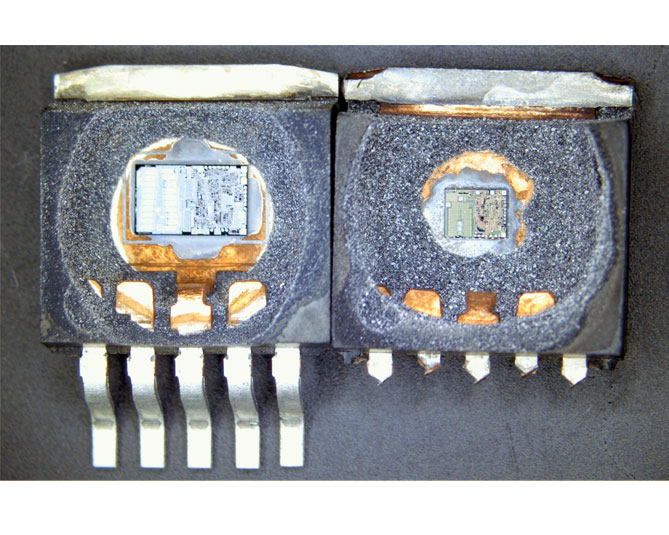

- Analysis in case of suspected misdeclaration, interior and exterior

- Wipe and solvent resistance tests, light (optical) microscopy, X-ray inspection, XRF, REM/EDX, chemical component decapsulation

- Wipe and solvent resistance tests, light (optical) microscopy, X-ray inspection, XRF, REM/EDX, chemical component decapsulation

- Comparison to reference components in every construction relevant detail

- Analysis of structural integrity

- Screening auf RoHS-Konformität / Bleifreiheit der Lötkontakte

The number of manipulated electronic components on the open market is rising steadily. Next to desoldered components, broken parts which do not meet the required parameters or even components with either an incorrect or without any DIE inside, for the most part relabeled components are proclaimed and sold as original products.

The ultramodern HTV analysis laboratory offers numerous

extensive services to perform evaluations regarding the originality and quality of supplied parts so that possible component manipulations can be uncovered. All this happens under the purview of the international SAE standard AS6081

The authenticity of the purchased parts is ensured by various detailed examinations of the component’s external appearance (i.e., inspection of incoming goods, light microscopy) as well as their internal structure after a chemical component decapsulation (i.e., chip identification). This evaluation is of essential importance, especially for electronic components of uncertain origin, in order to maintain the quality of one’s own products. For example, using a wipe test, in which the surface of the component is treated with special chemicals, it is possible to determine whether the component was relabeled or manipulated. Further analyses like solderability test or data sheet tests can be performed as well, to complement the visual evaluation of goods.