Analysis of cracks and delaminations via acoustic microscopy

Applied standards:

- IPC/JEDEC J-STD-035

- JEDEC J-STD-020

- AEC-Q100

- AS6081

- IDEA-STD-1010

- DIN EN 60749-35

- MIL-STD-883

- ESCC 25200

- PEM-INST-001

Applied in:

- Analyzing circuit boards and components in regards to delaminations or fractures

- Qualifying component housings (IPC/JEDEC J-STD-020)

- Non-invasive analysis of encapsulated assemblies

- Analyzing mechanical components or other work pieces in regards to cavities and voids

Acoustic microscopy (SAM) at HTV

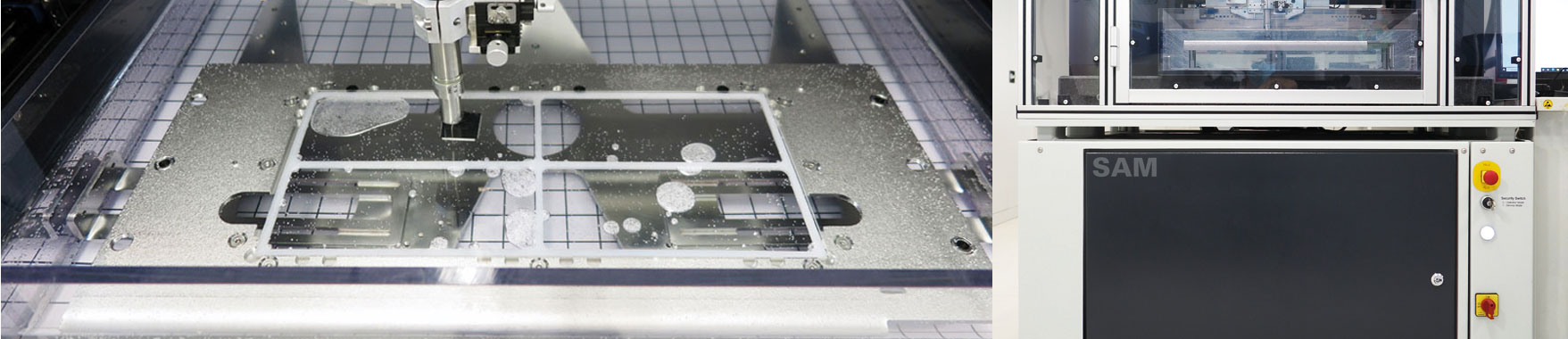

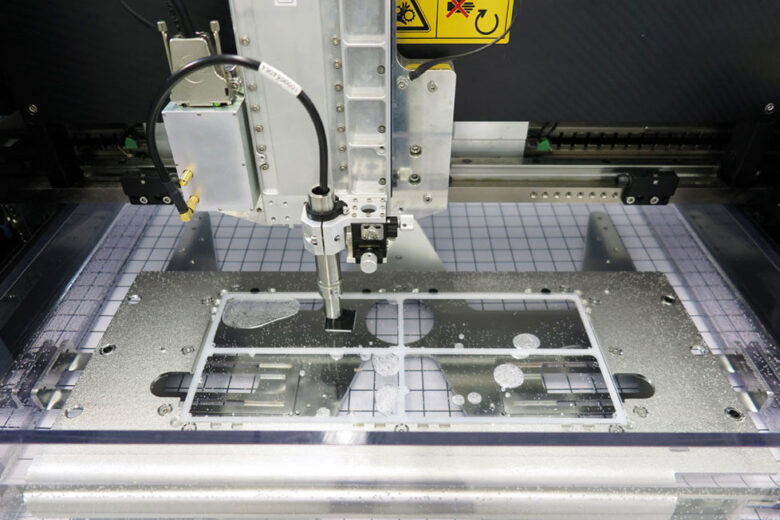

Scanning in process

Scanning acoustic microscopy, or SAM for short, is a non-invasive analysis method, using ultrasound. High frequency sound waves are applied to a sample and, depending on the measuring configuration, interpreted whether the signals are reflected or transmitted.

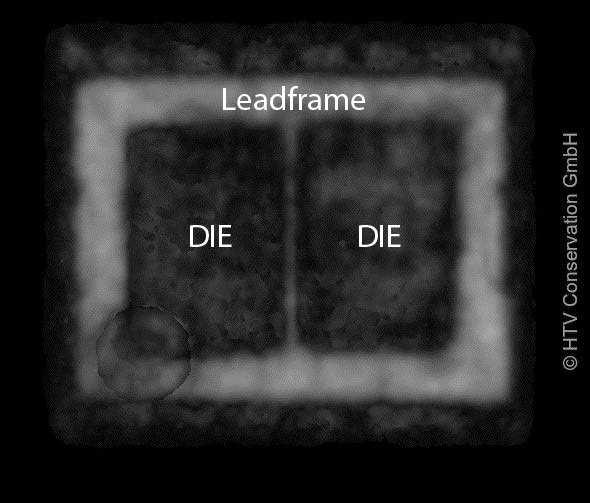

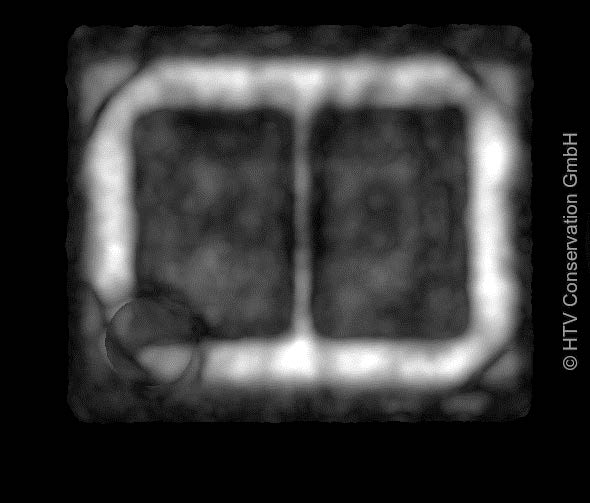

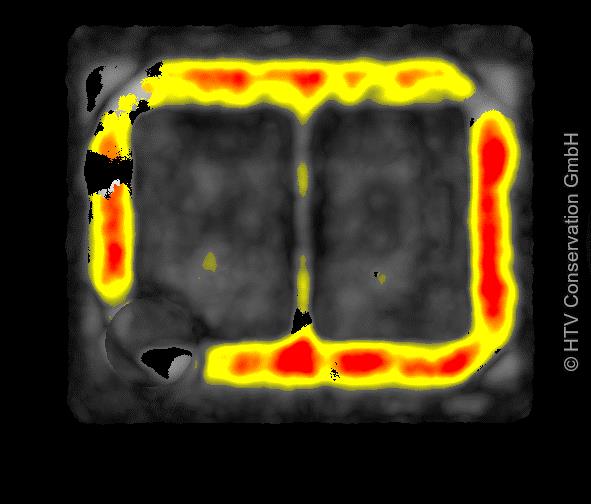

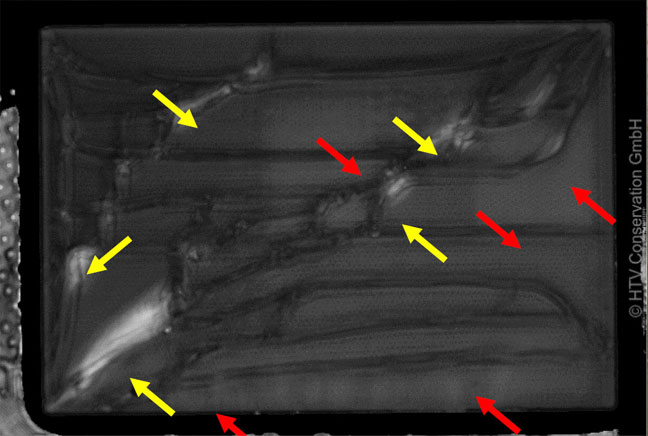

Based on the information contained in the measuring signal, i.e., runtime, amplitude and polarity, interfaces are examined and, if the speed of sound inside the material is known, layer thicknesses can be measured. Since sound waves are fully reflected with an interface exposed to air, SAM is especially useful to analyze cavities, i.e., bubbles in molds or delaminations in circuit board base material and component housing.

SAM is basically non-invasive; the sample only needs to be waterproof, as it is dipped into water which is needed as a carrier for the sound waves. Given the extremely flexible design and comprehensive equipment, the HTV ultrasound microscope can be used for the following scans:

- A-scan: Displaying the signal amplitude over time at a certain position

- B-scan: In-depth profile / vertical sectioning

- C-scan: Horizontal sectioning

- G-/X-scan: Several c-scans in one measurement / layer batch

- Z-scan: Tomographic 3D documentation/any section can be reconstructed

- Through-scan: Transmission

Given the great variety of transducers, basically the acoustic equivalent of optic lenses, the HTV Institute for Material Analysis can adapt their methods to all materials and structures.

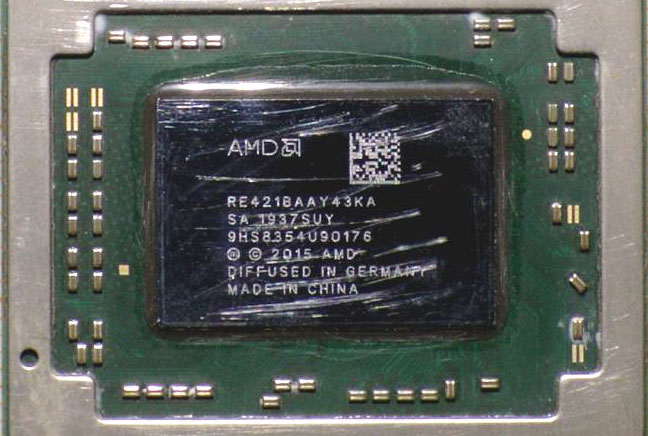

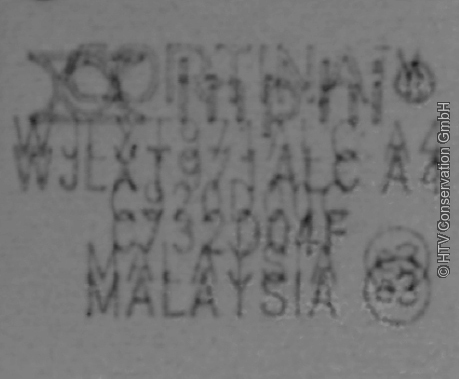

Recent counterfeiting techniques are becoming harder and harder to detect. Counterfeiters will grind off the old label, then mix the scrapings with epoxy to re-encapsulate the component’s surface, thus preserving the housing’s original appearance. Then the part can be labeled anew. The swab test is useless in this case (see image on the left). However, analyzing these parts with a SAM will uncover the truth, i.e., the original labeling.