Nanoindentation as a hardness testing procedure with mechanical and elastic parameters as an additional gain

Applied Standards

- DIN EN ISO 4516

- DIN EN ISO 14577-1

- ASTM E 2546

Areas of application:

- Ascertaining hardness in regards to material testing (Vickers hardness test, Brinell hardness test, Martens hardness test) as well as elastic and creep or cold flow properties

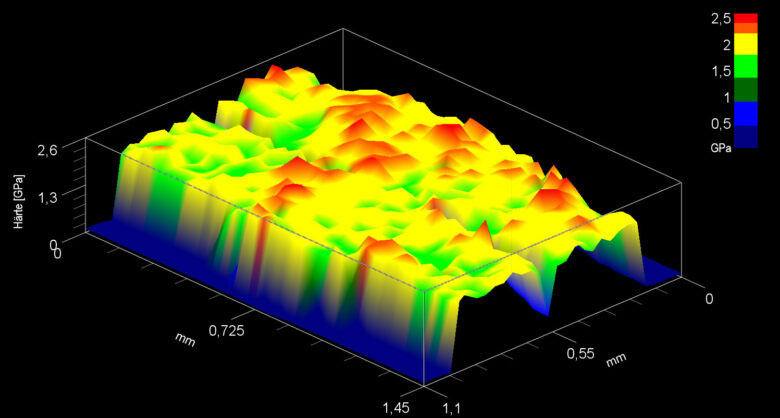

- Evaluating the mechanical properties’ homogeneity of polymers, metals or ceramics

- Analyzing thin layers (i.e., less than 1 μm thickness) not influenced by the base material

- Analyzing plastic and elastic transformations to investigate the aging process of polymers (brittleness evaluation)

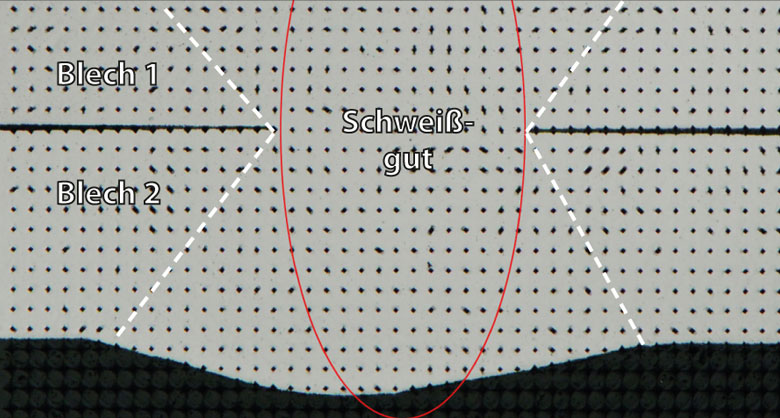

- Analyzing the hardness of welds in regards to microsectioning

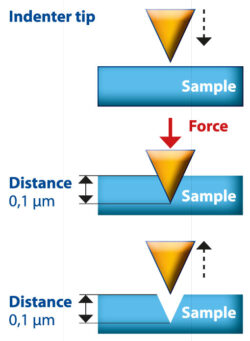

Nanoindentation describes a process, in which a diamond probe tip in the form of a pyramid is pressed into the sample’s surface. The intrusion force as well as the intrusion depth into the sample’s surface are measured simultaneously.

The data thus gained may then be used to ascertain several standard hardness parameters, such as the Brinell, the Vickers or the Martens hardness.

Unlike conventional invasive hardness testing methods, the precise and almost non-invasive nanoindentation makes it possible to ascertain several additional material properties and parameters even in the smallest sample dimensions (i.e., the nano and micro meter range).