HTV TAB®PLUS Long-Term Conservation and storage of assemblies and devices

- Assembly-specific aging processes are significantly reduced

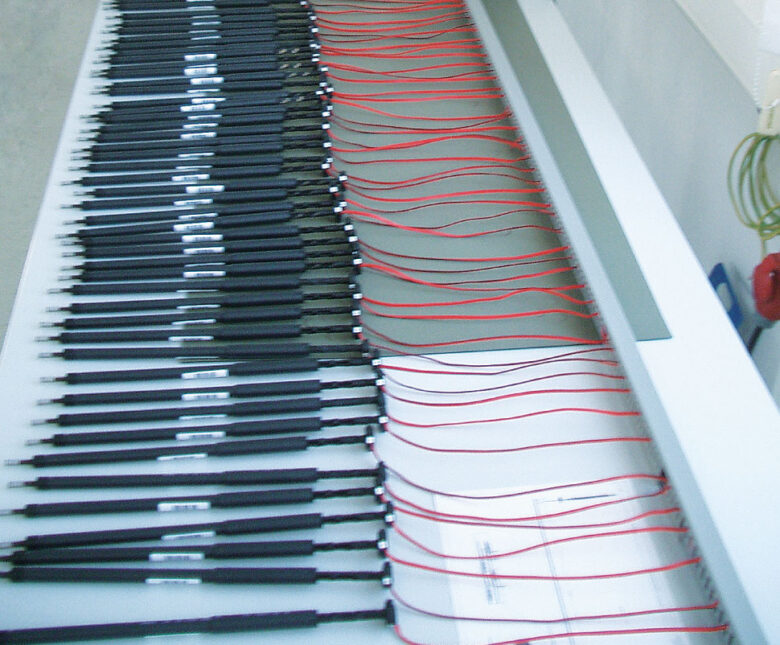

- Additional cyclic powering to operating voltage (energization)

- Availability of already certified and proven assemblies and devices not requiring a time-consuming and cost-intensive redesign process for up to 50 years, depending on the initial condition

Reasons for storing assemblies and devices

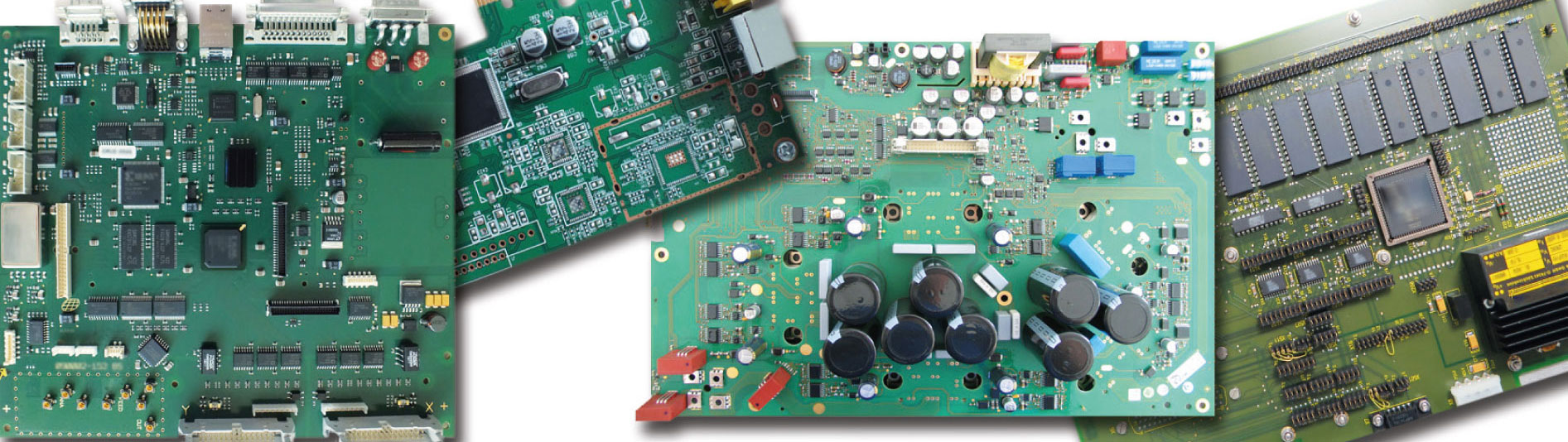

In addition to storing individual components, the long-term conservation of complete assemblies and devices is in many cases a reasonable and sometimes unavoidable option. Unlike component storage, no production equipment or manufacturing knowledge is required; the assemblies and devices are ready for immediate use and can be delivered to end customers or to the aftermarket, i.e., the spare parts market. Long-term storage is of an especially decisive importance for very durable products with elaborately certified assemblies, as any necessary redesign otherwise requires investing a great deal of time and money.

Due to the enormous variety of types and combinatorics of the individual components assemblies often show additional aging effects which can endanger the proper functionality of the entire assembly. Even during longterm storage outgassing from the used finishes and compounds as well as from the residues of the soldering process can lead to corrosion and oxidation of assembled components. In addition, capacitors (especially electrolytic capacitors) run the risk of changing their capacitance or increasing the leakage current during storage, which can result in total failure and thus destruction of the entire assembly. LC or OLED displays are also at risk of significant changes in their optical properties.

HTV TAB®PLUS Long-Term Conservation and storage of assemblies and devices as an obsolescence strategy

HTV TAB®PLUS also reduces module-specific aging processes due to specific storage conditions and a special conserving atmosphere which eliminates hazardous substances. A cyclic powering to operating voltage (energization) is part of the HTV TAB®PLUS process since frequently energized assemblies operate much more resistant and reliable than only sporadically and rarely used devices.

Due to decades of experience as well as continuous research and development a wide range of different assemblies and devices can be stored by means of a special adaptation using the HTV TAB®PLUS method, e.g.:

- Server systems

- (Power) inverters

- Single-board computers

- Displays and monitors

- Sensor systems

- Assemblies of automation systems

- Control technology

- Automotive lighting technology

An additional advantage of cyclic energization is the elimination of early failures: assemblies and devices that otherwise would fail at the customer‘s premises shortly after switching on are already detected and sorted out in the HTV laboratory.