Fully automated solderability test to evaluate the processability of electronic components

Applied Standards

- J-STD-002

- J-STD-003

- DIN EN IEC 60068-2-20

- DIN EN 60068-2-58

- DIN EN 60068-2-69

- MIL-STD-883

- MIL-STD-202

- VDE 0468-2-20

- VDE 0468-2-58

- VDE 0468-2-69

- IDEA-STD-1010

Areas of application:

- Testing the solderability of components, printed circuit boards, SMD pads and plated-through holes

- Measuring wetting strength

- Ascertaining the processability of components during the soldering process

- Analyzing problems appearing in the context of the soldering process

- Ascertaining the solderability variances of different component batches/components of varying ages

- Monitoring the state of solderability across a pre-defined time span

Components of a rather advanced age specifically suffer from the problem of qualitatively and quantitatively ascertaining their solderability.

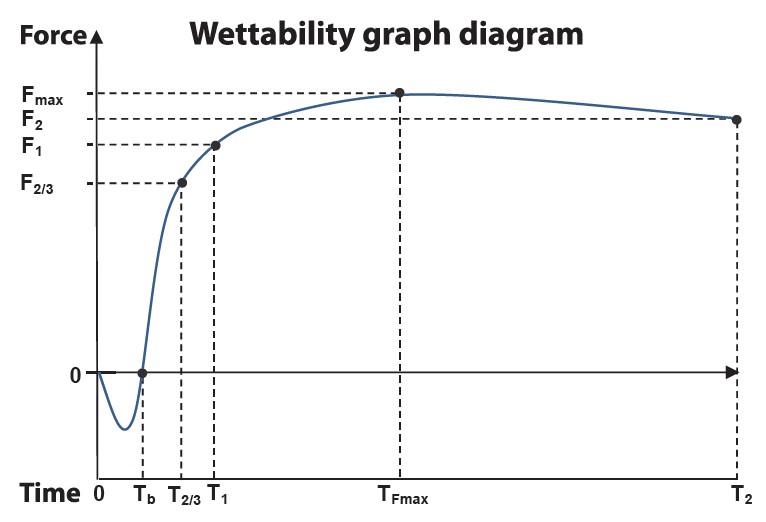

Highly precise, fully automated solderability testing systems make it possible to determine and document the exact wetting strength, i.e., ascertaining the force which keeps the sample immersed, of each individual component pin by dipping the sample into liquid solder.

Following this, the probable processability can then be estimated from the progression of forces as well as their maximal gained amoint. Alternatively, depending on the component’s housing, the component is analyzed with a Dip & Look test.

Further advantages of the fully automated solderability test:

- Graphical, color-based representation of the test results

- Quantitative evaluation of the wetting forces Aussage über die Benetzungskräfte

- Video documentation

- Very reproducable