Compatible packing for every kind of component housing

Applied standards

- DIN IEC 60286

Areas of application:

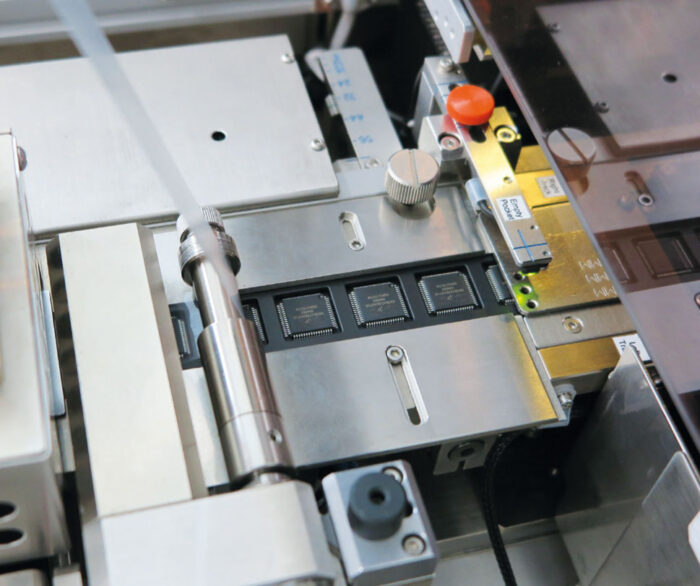

- Taping & reeling, fully automated, including a 3D component inspection

- Taping in accordance with valid standards (SMD, axial or radial taping & reeling)

- Taping of non-standardized housing shapes

- Developing specific tapings as per customer request, such as for an automated assembly of mechanical components or printed circuit boards

- Rotating the components inside the tape

- Repacking in other types of packing (tape, tray or tube goods)

- Further taping services:

- Reparing and/or renewing the masking tape and/or the reel tape

- Refilling empty tape pockets

- Adding the leader and trailer to blister tape

Many SMD assembly lines exclusively process taped components these days to save valubale space in the manufacturing’s feeder line. Therefore, following a test, a programming, marking and a 3d lead inspection, at HTV electronic components are packaged into a blister tape using fully or semi automated taping & reeling systems.

Given the enormous variety of component housing types, HTV’s very own and very well organized raw tape storage with almost 1000 different tapes ensures a swift availability of any necessary and compatible tape.

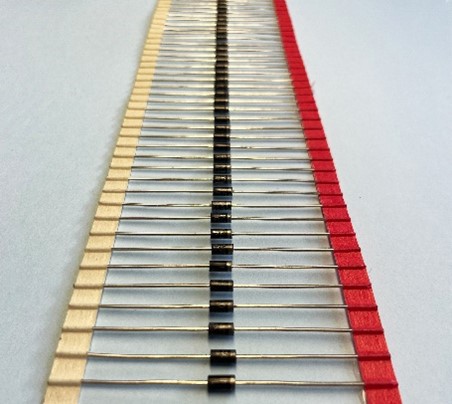

Axial Taping&Reeling

Our axial taping&reeling is performed according to either the IEC60286-1 standard or to customer specifications.

We require a component blueprint, preferably the manufacturer’s original datasheet, to quote you your individual and non-committal price.

Our axial tapes are the ideal solution for the precise handling of axial components, such as resistors, capacitors, diodes or other wired components. The electrical connections of these components are an elongation of the component’s longitudinal axis, which makes positioning them as exactly as possible of vital importance. Our axial tapes make it possible to efficiently process and precisely position these components, which in turn allows for a smooth manufacturing process.

Radial Taping&Reeling

Our radial taping&reeling is performed according to either the DIN EN I EC 60286-2 standard or to customer specifications.

We require a component blueprint, preferably the manufacturer’s original datasheet, to quote you your individual and non-committal price. Whether it’s a reel or an ammo pack, HTV GmbH can provide all standard bending forms for changing the grid and naturally tapes & reels everything in accordance to current standards.

Our radial tapes can provide you with an innovative solution for the handling of electronic components such as LEDs and various capacitors. Using through hole technology (THT) the components are placed on a paper tape, with their connectors led out on one side and precisely positioned. This enables an efficient processing and a reliable placement of the components for optimal product quality.