Drying electronic components to avoid component damages during soldering (Baking)

Applied standards

- J-STD-033

Areas of application:

- Standardized component drying in accordance with J-STD-033

- HTV-PLUS vacuum drying

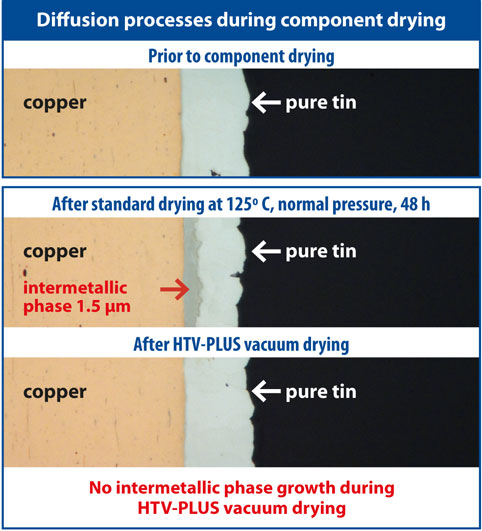

- A smooth HTV standard method to prevent diffusion (aging processes) during the drying process

A too high moisture level inside electronic components is a decisive factor in regards to damages during the manufacturing process (i.e., the popcorn effect).

Standardized drying in accordance with J-STD-033

Using the standardized component drying in accordance with J-STD-033 reduces moisture inside the component and ensures that it can be processed without being damaged during the soldering process. Recommended drying temperatures range from 125 °C to 90 °C to 40 °C (respectively from 257 °Fahrenheit to 194 °Fahrenheit to 104 °Fahrenheit), yet a lower temperature requires a longer dry cycle (possibly up to 79 days).

That being said, this is a sticking point of the standardized drying in accordance with J-STD-033. From an economic point of view the only viable drying temperature is 125 °C (257 °Fahrenheit) since the dry cycle only requires a time span between 5 and 48 hours.

However, higher drying temperatures also increase aging processes (such as intermetallic phase growth, oxidation of the pin contact surfaces) which negatively affect the reliability of the soldering process. During a dry cycle of 48 hours at 125 °C (257 °Fahrenheit) an intermetallic phase growth (diffusion of the copper inside the component pin into the tin coating of the pin’s surface and the formation of an intermetallic phase alloy) of 1,5μm happens, which endangers any further processing, as an intermetallic phase of more than 2μm inhibits a reliable soldering. Should there already be an intermetallic phase of more than 1μm (which is equal to an intermetallic phase growth at room temperature over a time span of 2,5 years) or should the drying process be repeated, the limit of 2μm is quickly surpassed.

HTV-PLUS vacuum drying as an economic and smooth alternative

The HTV-PLUS vacuum drying prevents the formation and/or continuation of diffusion processes at low temperatures, including the intermetallic phase growth, and thus a progression of the component’s aging. As an added bonus, the HTV-PLUS vacuum drying can be applied to dry taped and reeled IC components as well as tubed ones. Expenditures of time and money are no longer a factor.