International SAE standard AS6081 for investigating and discovering counterfeit components

25. August 2022

HTV’s Institute for Material Analysis offers expertise in accordance with the international SAE standard AS6081 for the detection of counterfeit electronic components:

Prevention, detection, mitigation and disposal

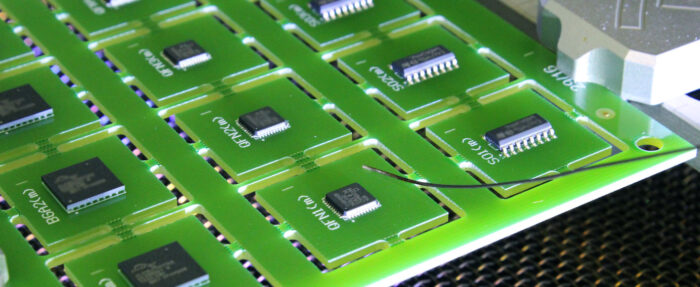

With the addition of scanning acoustic microscopy (SAM) the inspection methods of HTV’s proprietary Institute for Material Analysis offer everything from X-ray inspection, inspection of solder contact coatings using XRF or SEM/EDX, to chemical component decapsulation, thermal cycling, electrical tests and burn-in testing, i.e. the entire range of inspection methods as required by the SAE standard AS6081.

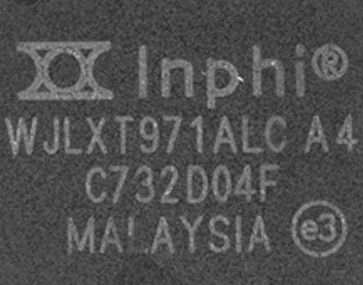

Figure 1: Counterfeiters have developed new techniques which are becoming increasingly difficult to detect. The old label is filed off; the filings are mixed with epoxy resin then re-applied to the surface of the component. This preserves the housing’s original appearance. Afterwards the parts are re-labeled. A wipe test of such a component yields no visible results (left). However, a closer examination using a scanning acoustic microscope (SAM) brings the original label, and thus the truth, to light.

AS6081 standard

The AS6081 standard was created in response to the significant and increasing volume of counterfeit electronic components ending up in supply chains of the aerospace industry, which poses considerable risks to performance, reliability and safety.

AS6081 contains consistent requirements, practices and methods for mitigating the risk of counterfeit components in the supply chain. The standard specifies the proactive identification of reliable sources for components, evaluation and mitigation of the risks posed by counterfeit components, inspection requirements, controlling of components discovered to be counterfeit, and reporting of suspected and confirmed counterfeit parts.

EEE components

When buying EEE (electrical, electronic and electromechanical) components with the intention to sell them to the US military, products acquired outside of original equipment manufacturer channels, i.e. on the free market, must be tested according to the AS6081 standard.

Especially given the current market situation, which forces many manufacturers to purchase components from questionable sources due to the global IC shortage, compliance with this strict standard is just as beneficial for electronic components intended for commercial or industrial use.

The HTV Institute for Materials Analysis is one of the few testing facilities in Germany to offer AS6081-compliant testing, which is considered one of the best ways to sort out substandard parts that could affect product or system performance.

See also: Goods evaluation to determine component counterfeits/manipulations (fakes).